Products

Categories

- Home

- Specialty Gas Equipment

- Gas Delivery Systems

- Gas Cabinets

- Hydrogen Gas Cabinet (2 Cyl) with Switchover System

Product Description

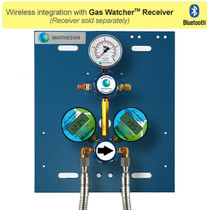

Matheson offers a configured two cylinder gas cabinet with a stainless steel switchover for hydrogen service. All piping penetrations are through the top of the cabinet through a bulkhead plate.

Standard Configuration

• 1178 Two Cylinder Gas Cabinet

The Model 1170 is our most popular gas cabinet series with a flat top design. The construction is optimized for economy, without compromising safety or quality.

Standard Configuration

• 200 psi +/- 20 psi switchover pressure

• 3 foot long flex hoses

• Process Gas Outlet: 1/4" Compression

• Flex Hose: 350 CGA

Switchover Options

• Valves

High Pressure Isolation (HPI) valves are useful when you want to isolate a single side for maintenance or cylinder changes. The HPI valve/High Pressure Vent (HPV) valve option enables the user to maintain optimum purity after cylinder changes.

| Low Cylinder Indication |

|||

| Intrinsically Safe Pressure Switches The Class 1 Div 1 & 2 intrinsically safe pressure switches are the Ashcroft F series and are useful when remote monitoring of a gas supply is desired. The are set to 300 psi decreasing and can be adjusted by the customer. |

|

||

| Pressure Monitor (PM-24) The Matheson Pressure Monitor, Model PM-24, was designed as a method of monitoring a gas supply, when used in conjunction with Matheson Gas Delivery Systems with Pressure Switches. The PM-24 will indicate the status of both sides of the switchover: FULL – IN SERVICE, and DEPLETED. When a cylinder or cylinder bank is depleted, the green light will change to a red light, and the audible alarm will sound. The audible alarm can be silenced, leaving the red light indication. The red light will automatically reset to green when the depleted cylinder is replaced with a full cylinder. |

|

| Recommended Safety Package |

|||

| Gas Detection The Hydrogen LEL (GSM Series) Gas Sensor is able to detect any dangerous leaks and is typically coupled with a GSM-12 Controller and an ESO valve. |

|

||

| GSM-12 Shutdown Controller< The GSM-12 controller is typically used to operate a pneumatically operated, normally closed, emergency shutoff valve (ESO) on a gas panel. It has ten sets of contacts for alarm conditions: • Excess Flow • Exhaust Failure • Gas Detector Warning • Gas Detector Alarm • Fire Detector • Low Cylinder Contents (by pressure or weight) • High Delivery Pressure • Process Line Containment • Remote Start • Remote Shutdown (Sensors ordered separately) Delay times between when a fault condition is first sensed and when an actual shutdown or alarm occurs have been programmed to avoid any nuisance alarm tripping.The controller also has an ABORT button on the front for manual shutdown. |

|

||

| Emergency Shutoff Valve (ESO) The 4384 Series Air Operated Valve is Normally Closed (NC). The are installed at each inlet of the switchover and are operated by the GSM-12 Controller. It has a diaphragm seal for high purity and low diffusion. |

|

Other Options

| Other Shutdown Options |

|||

| Excess Flow Switch (EFS) The excess flow switch (Size D) is installed on the outlet of the switchover and is typically coupled with a GSM-12 Controller and an ESO valve. The set point increases when the pressure increases and will trip between 10 and 20 SLPM (30 PSI) |

|

||

| Excess Flow Valve (EFV) The 6290 Series Excess Flow Control Valve is a sensitive excess flow shut-off valve installed on the outlet of the switchover and is designed to operate with a wide range of inlet pressures. |

|

||

| Exhaust Failure Switch (option X) Switch used to indicate low exhaust suction. This is a popular option with the GSM-12 |

|

| Ventilation Options |

|||

| Magnahelic (option M) Gives visual status of exhaust suction (option M). This is often paired with the exhaust failure switch Range: 0-3" WC |

|

||

| Fusible Link (option L) Blocks air from entering cabinet in case of fire. Temperature rating: 165 F Approvals - UL & C-UL Listed and FM Approved |

|

||

| Diffuser Plate with Filter (option D) To prevent small particulates from entering the cabinet interior. |

|

Loading... Please wait...

Loading... Please wait...