Products

Categories

- Home

- Specialty Gas Equipment

- Gas Delivery Systems

- Source Manifolds

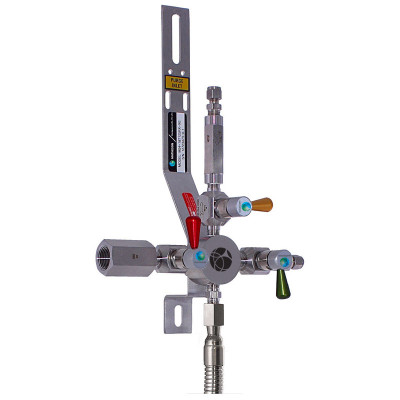

- 54 Series Cross Purge Station (SS)

Product Description

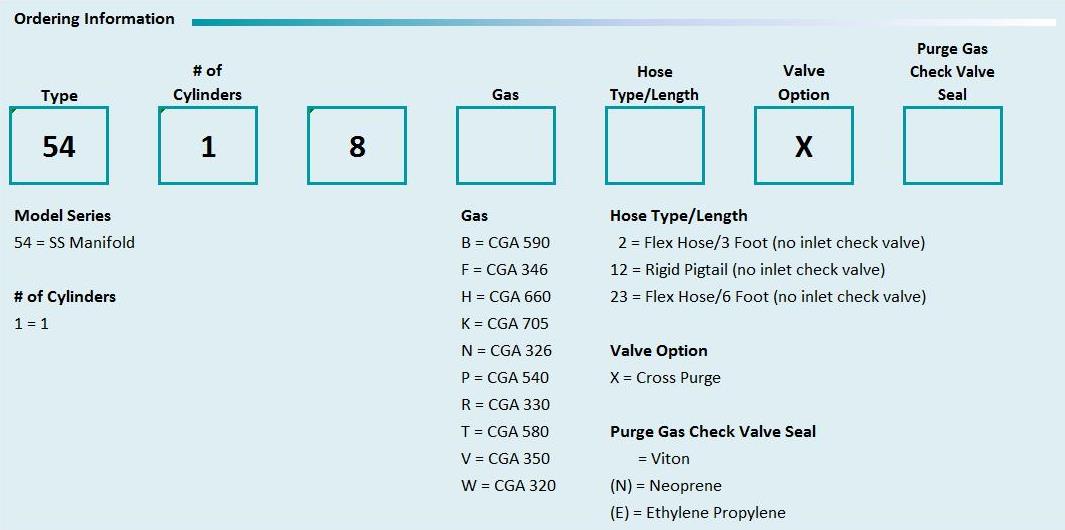

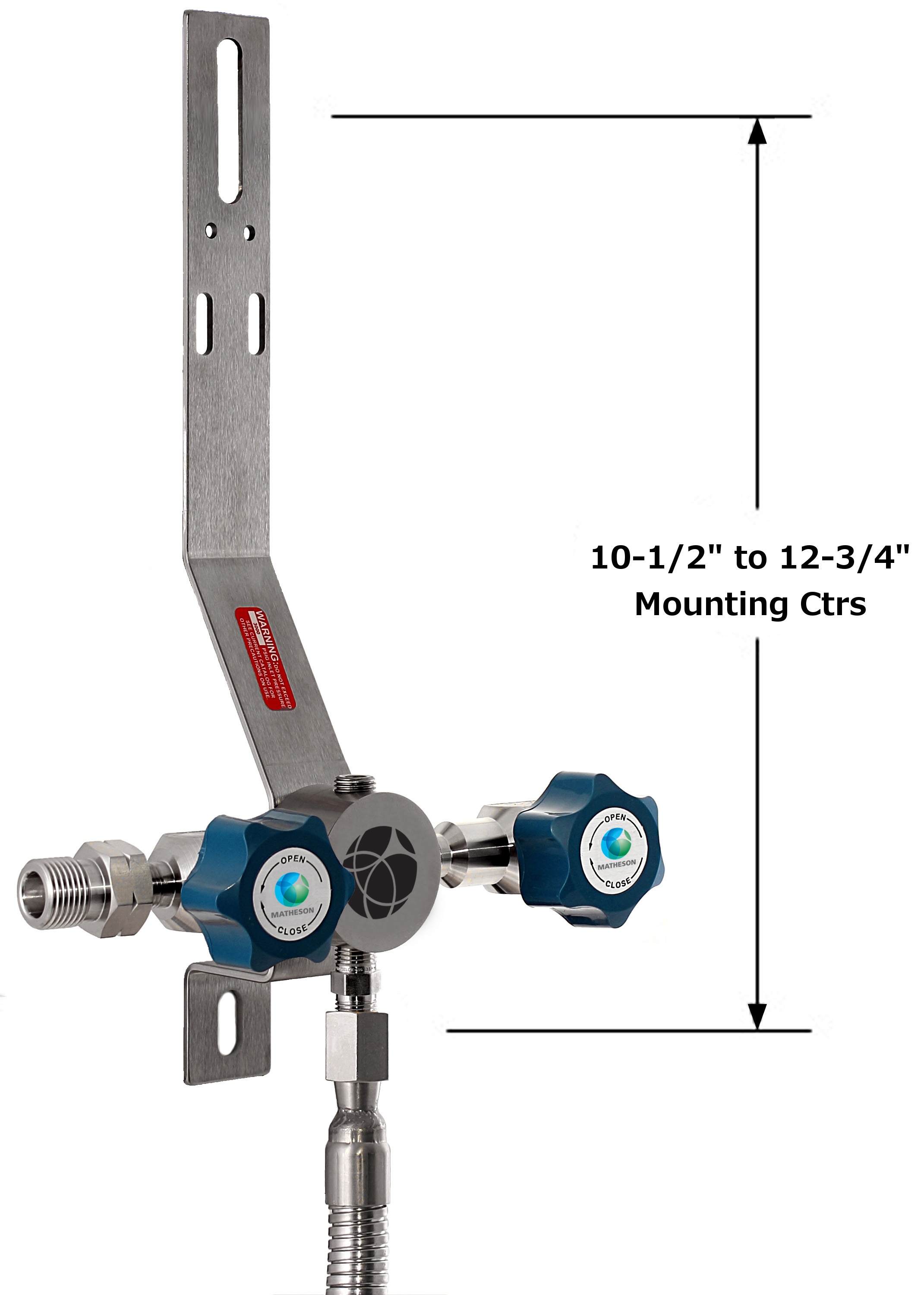

The Matheson 54 Series Cross Purge Station provides effective purging during cylinder changes and can be conveniently mounted to a wall. The assembly which contains a vent, isolation, and purge gas valve is highly recommended when using toxic or corrosive gases and is also intended for use with high purity applications where preventing contaminates such as air and water vapor is critical. Atmospheric contaminants become trapped in the high pressure portion of the regulator upon connection to another cylinder. If allowed to remain they are swept into your system. Depending upon your flow rate and desired purity level, these impurities can disrupt your process for days or even weeks. Purging with an inert gas will also remove residual toxic or corrosive gases before changing out cylinders. These cross purge stations may be used with many of Matheson’s stainless steel regulators (regulators sold separately).

Dry nitrogen or clean dry air (50 -100 psi) needs to be supplied to the cross purge.

Design Features

• All Stainless Steel Construction

• Fast-acting 4360 series quarter-turn diaphragm valves

• Color coded handles indicate condition of valve and direction of flow when opened

• Check valve on purge gas inlet to prevent contamination of purge gas line

• Outlet CGA fitting for ease of regulator installation

• Available with either a flex hose or rigid pigtail

Standard Configuration

• Stainless Steel manifold block

• Heavy duty stainless steel mounting bracket

• 3 foot long Armored Stainless Steel flex hose

• CGA connection (No integral check valve)

• Right Side Cylinder Set-Up (gas outlet is on left side)

• Purge Gas Inlet (PGI) with Check Valve: 12:00 position

• High Pressure Vent (HPV) Valve: 3:00 position

• Flex Hose/Rigid Pigtail: 6:00 position

• High Pressure Isolation (HPI) Valve with CGA Bushing: 9:00 position

• Mounting holes for 3/8” screws

Options

• Flex Hose/Rigid Pigtail

The standard three foot long hose work well with cylinders that can easily be secured close to the manifold. Six foot long hoses are useful when hard to position cylinder bundles or when dewars are the gas source. Rigid pigtails should be chosen for corrosive or toxic gases as purging is more effective with rigid pigtails than with flex hoses.

• Check Valve Seal Material

Viton is the standard seal material in the purge gas check valve. If your gas is not compatible with Viton then Neoprene or Ethylene Propylene seals can be selected. If you are not sure of the compatibility of your gas then check out this fluid compatibility guide.

Options (sold separately)

• Pressure Regulator

• 3610A Series -Tied Diaphragm (Corrosives)

• 3810A Series - Dual Stage

• 3510A Series - Single Stage

• 3030S & 3040S Series - High Pressure

Specifications

• Valves and Fittings: Stainless Steel

• Manifold Block: Stainless Steel

• Flex Hose/Rigid Pigtail: Stainless Steel

• Purge Gas Inlet: 1/4" compression fitting

• Vent Connection: 1/4" compression fitting

• Outlet Connection: CGA Bushing

• Maximum Inlet Pressure: 3000 psi (depending upon CGA rating)

Loading... Please wait...

Loading... Please wait...