Products

Categories

- Home

- Specialty Gas Equipment

- Regulators

- Dual Stage Regulators

- 3810A Series Dual-Stage High-Purity Regulator - SS

Product Description

High-purity regulators designed for analytical applications using non-corrosive or semi-corrosive gases.

Applications

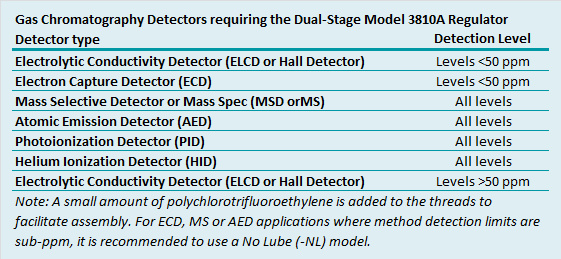

• Supply of carrier gas/detector support gas for a variety of gas chromatography applications (see table below for details).

• Supply of calibration standards to on-line process analyzers, emission monitoring systems, etc.

• Supply of high-purity non-corrosive or semi-corrosive gases to applications requiring constant delivery pressure.

MATHESON strongly recommends the use of a cross-purge with any regulator put into highly corrosive or toxic gas service. You can easily add a cross-purge to this model regulator by selecting "Yes" for the Cross Purge option above.

Looking for something a little bit different? Different inlet or outlet fitting or remove the outlet valve? Check out our Modified 3810A Pressure Regulator.

Design Features

• High-purity 316L stainless steel barstock body

• High-purity 316L stainless steel diaphragm

• Metal to metal seals minimize diffusion of contaminants

• 2” inlet and delivery pressure gauges

• Bonnet ported and threaded to pipe gases away from work area

• Equipped with outlet diaphragm valve

• 1/4” compression tube outlet connection

• 10 micron metal filter protects seat from contamination

• Optional interstage relief valve available

• Panel mountable, front and back bonnet threaded

• Bonnet vent hole size: 1/8” NPTF

| Part Number* | Max Delivery Pressure |

Delivery Pressure Gauge |

Cylinder Pressure Gauge |

| SEQ3811ACGA | 15 psi | -30"-0-30 psi | 0-4000 psi |

| SEQ3813ACGA | 50 psi | -30"-0-100 psi | 0-4000 psi |

| SEQ3810ACGA | 125 psi | -30"-0-200 psi | 0-4000 psi |

| SEQ3816ACGA | 250 psi | 0-400 psi | 0-4000 psi |

| SEQ3818ACGA | 500 psi | 0-1000 psi | 0-4000 psi |

*Note: where CGA is replaced by the actual CGA number. Some CGA limitations may apply. (NI) for 1/4" FNPT inlet

Materials of Construction

• Gauges: 316 stainless steel

• Body: 316L stainless steel

• Bonnets: Chrome plated brass barstock

• Diaphragms: 316L stainless steel

• Seats:

1st Stage – Teflon

2nd Stage – Teflon

• Seals: Metal to metal

• Valve Body (4370 Series): 316L stainless steel

• Valve Diaphragm: 316L stainless steel

• Valve Seat: PCTFE

Specifications

• Maximum Inlet Pressure: 3000 psi (20,700 kPa)

• Typical Max Flow Rate (100 psi del press): 7 SCFM-N2 (200 SLPM)

• Flow Capacity (Cv): 0.06

• Interstage Pressure

Model 3811A: ~350 psi

Model 3813A: ~350 psi

Model 3810A: ~350 psi

Model 3816A: ~350 psi

Model 3818A: ~560 psi

• Operating Temperature: -40°F to 140°F (-40°C to 60°C)

• Porting (Regulator Body): 1/4” NPT Female

• Porting Configuration: 2 High, 3 Low, l Interstage

Options

Cross Purge

• Eliminates the escape of hazardous gases when changing cylinders

• Reduces danger of contamination from atmospheric moisture and oxygen

• Minimizes the amount of gas lost during cylinder changes

• 4360 Series Quarter-Turn Diaphragm Valves used throughout

• All stainless steel construction (4774 Series Cross Purge)

Flow Curves

Flow Curves, 3120A/3810A Series

Instructions

Instructions, General Regulator

Loading... Please wait...

Loading... Please wait...