Products

Categories

- Home

- Specialty Gas Equipment

- Gas Delivery Systems

- Gas Cabinets

- 1177F Cabinet with 5000 Series Analytical Grade Panel

Product Description

Matheson offers a configured single cylinder gas cabinet with a 5000 Series Analytical Grade Panel. All piping penetrations are through the top of the cabinet through a bulkhead plate.

Warning: This gas cabinet is not suitable for silane service.

Standard Configuration

• 1177 Single Cylinder Gas Cabinet

The Model 1170 is our most popular gas cabinet series with a flat top design. The construction is optimized for economy, without compromising safety or quality.

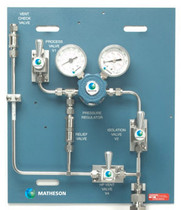

• 5000 Series Panel

Matheson's PAN-5000 Series of analytical grade stainless steel gas panels that are designed to safely control and dispense gases, while providing a high level of process purity. The PAN-5000 Series panels feature Matheson components that have a proven track record in analytical laboratories and chemical process industries worldwide. Use of these analytical distribution panels with a Matheson gas cabinet enclosure provides the high level of safety required when handling corrosive, flammable or toxic gases.

Panels

• 5100 Series

The 5100 Series Panel is most basic panel design which offers a pressure regulator and process on/off control valve. Connection to the gas supply is conveniently made using a standard stainless steel flexible hose. This panel is recommended when using inert gases with processes that do not require purge capability. Each CGA contains an integral check valve.

• 5300 Series

This 3-valve panel provides a pressure regulator with both a process on/off control valve and a high pressure vent valve, allowing total isolation of the regulator, as well as the ability to purge contaminants that may have been introduced by changing cylinders. The vent line is protected from back flow by a check valve downstream of the vent valve. This panel is recommended when using non-toxic, non-corrosive, and non-pyrophoric gases with processes that require the additional purity that a high pressure purge is capable of supplying. Each CGA contains an integral check valve.

• 5500 Series

This 5-valve panel provides all the same features as a 3-valve panel with the addition of a low-pressure vent valve, and adds the safety feature of being able to cycle purge the panel with an inert gas prior to disconnecting the cylinder. This panel provides the safety needed to handle toxic, semi-corrosive and flammable gases. The 5-valve panel is available with an optional venturi for vacuum evacuation of the panel during purging. Unlike the 1- and 3- valve designs, CGA’s do not contain integral check valves.

Panel Options

• Emergency Shutoff Valve (ESO)

This 4384 Series Air Operated Valve is Normally Closed (NC). It is installed at the inlet of the 5000 Series panel and is typically coupled with a GSM-12 Controller and Excess Flow Switch (EFS). It has a diaphragm seal for high purity and low diffusion.

• Excess Flow Switch (EFS)

The excess flow switch (Size D) is installed on the outlet of the 5000 Series Panel and is typically coupled with a GSM-12 Controller and an ESO valve. The set point increases when the pressure increases and will trip between 10 and 20 SLPM (30 PSI - N2).

• Excess Flow Valve (EFV)

The Model 6290 Series Excess Flow Control Valve is a sensitive excess flow shut-off valve designed to operate with a wide range of inlet pressures. It is installed on the outlet of the 5000 Series Panel.

Gas Connections

• Process Gas Outlet: 1/4" Compression

• Vent Valve Outlet (option): 1/4" Compression

• Purge Gas Inlet (option): 1/4" Compression

| Cylinder Options |

|||

| Chain for Cylinder(s) (option 1) for extra cylinder security |  |

||

| Shelf for Cylinder(s) (option S) Supports small cylinders higher in the cabinet for ease of interaction |  |

| Ventilation Options |

|||

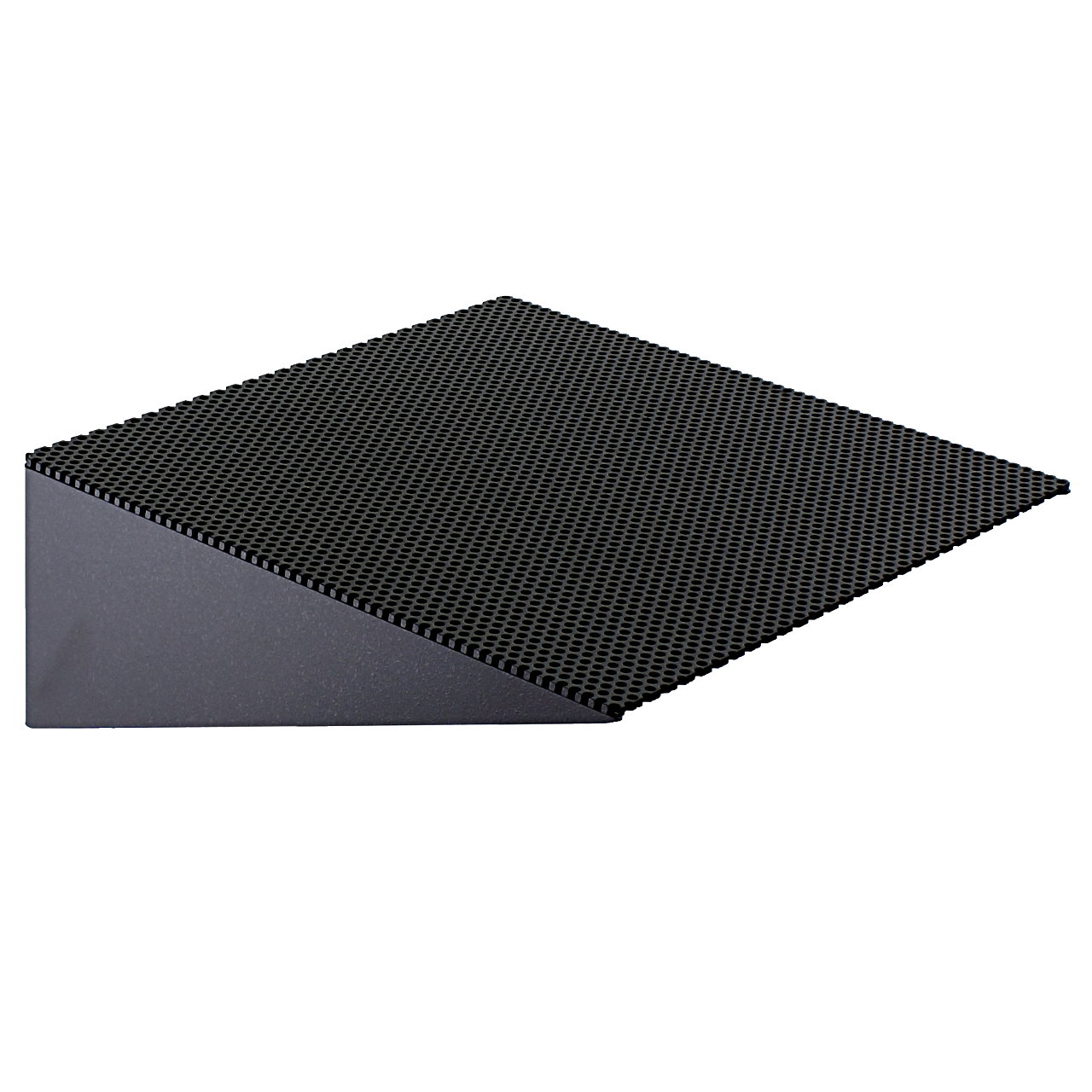

| Diffuser Plate with Filter (option D) To prevent small particulates from entering the cabinet interior. |

|

||

| Fusible Link (option L) Blocks air from entering cabinet in case of fire. Temperature rating: 165 F Approvals - UL & C-UL Listed and FM Approved |

|

Loading... Please wait...

Loading... Please wait...