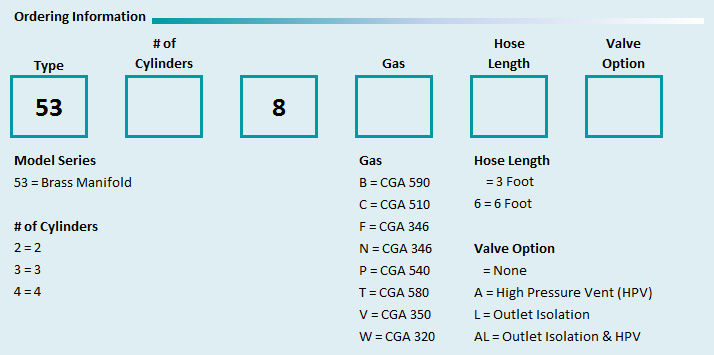

Products

Categories

- Home

- Specialty Gas Equipment

- Gas Delivery Systems

- Source Manifolds

- 53 Series Cylinder Manifold (Brass)

Product Description

Matheson’s SourceTrakTM Manifold Systems offer a safe and efficient method of connecting multiple cylinders to a common gas supply line to provide centralized distribution of gas for both high and low purity delivery requirements. SourceTrakTM Manifold Systems can be used as a manually operated system in conjunction with a line regulator to regulate downstream delivery pressure, or they can be used as an integrated part of Matheson’s Automatic Switchover Systems (see SwitchProTM). Utilizing SourceTrakTM Manifold Systems for the distribution of gas provides greater safety in the cylinder storage area by reducing repetitive cylinder handling and also minimizes the risk of ambient contamination within the gas delivery network.

The SourceTrakTM Manifold Systems can be furnished in brass or stainless steel materials to provide delivery service for a broad range of gases and are rated for pressures of up to 3000 psi. All SourceTrakTM Manifold Systems are single row configurations and are provided with the manifold piping, station (diaphragm) valves, 3-ft. flex hose, integral check valves, and manifold mounting brackets/clamps as standard components. The SourceTrakTM Manifold Systems are designed for "right side" cylinder set-up, where the gas flows from right to left through the manifold piping.

Standard Configuration

• Heavy Duty Manifold Piping

• Station Valves (Diaphragm) for each cylinder

• 3 foot long Armored Stainless Steel flex hose

• CGA connection with integral check valve

• Right Side Cylinder Set-Up (gas outlet is on left side)

• Mounting Brackets & Clamps

Options

• Hoses

The standard three foot long hoses work well with cylinders that can easily be secured close to the manifold. Six foot long hoses are useful when hard to position cylinder bundles or dewars are the gas source

• Valves

High Pressure Isolation (HPI) valves are useful when you want to isolate a single side for maintenance. The HPI valve/High Pressure Vent (HPV) valve option enables the user to maintain optimum purity after cylinder changes. (Vent Valve option not for Acetylene service)

Materials of Construction

• Manifold Header: Brass

• Station Valves: Brass/Kel-F Seats

• Cylinder Connections and Fittings: Brass

• High Pressure Vent Valve (option): Brass

• High Pressure Isolation Valve (option): Stainless Steel

• Flex Hoses: Stainless Steel

Specifications

• Station Valve Spacing: 12" centers

• Station Valves: Full Turn Diaphragm type

• Station Valve Inlet: CGA 346 Bushing

• Station Valve closing torque: 7.5 - 10 ft-lbs

• Header Porting: 1/2" FPT

• High Pressure Vent Valve (option): Full Turn Diaphragm type (4370 Series-Brass)

• High Pressure Isolation Valve (option): Full Turn Diaphragm type (SEQVLV1752SA)

• Flex Hoses: Armored (

• Maximum Inlet Pressure: 3000 psi (depending upon CGA rating)

• Outlet Connection: CGA Bushing for regulator attachment

Instructions

Drawings

3D Models

Manifold, 2 cyl, stdManifold, 3 cyl, stdManifold, 4 cyl, std

Loading... Please wait...

Loading... Please wait...