Products

Categories

- Home

- Specialty Gas Equipment

- Filters and Purifiers

- Weld Knight™ NANOCHEM® Welding Gas Purifier

Product Description

NANOCHEM® Weld Knight™ purifiers provide purge and shield gas purification for welding applications. Weld gas impurities, such as moisture and oxygen, adversely affect weld quality. These impurities are present in gas cylinders and can also be introduced through leaks in the line or during cylinder changes.

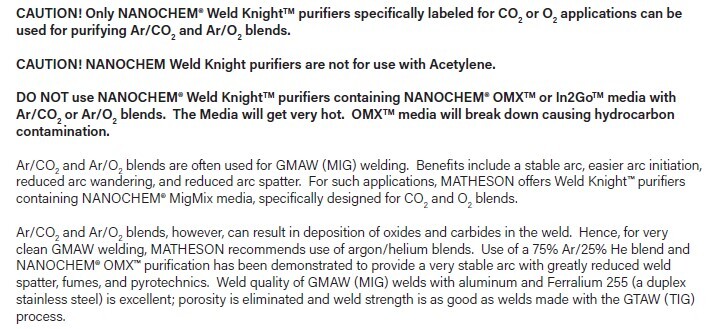

NANOCHEM® OMX™ and INX-Plus™ media react chemically and irreversibly with these impurities to deliver consistently pure gas to the weld site, improving weld quality. NANOCHEM® MigMix media is specifically designed to purify Ar/O2, Ar/CO2 and other O2, or CO2 blends.

NANOCHEM® MigMix provides customers with the ability to use blended gas without the worry of reducing their tolerances or dilution ratios. MigMix is also better than any media for the removal of moisture impurities.

NANOCHEM® Weld Knight™ purifiers are an economical solution for GMAW (TIG) welding and other critical welding applications.

• Flow Rates up to 530 cfh (250 slpm)

• Easy to use canister bypass mode for canister changes and extended shutdowns

• Field replaceable canisters available

• Canister can be refilled, enabling savings over purchase of spare canisters

Features and Benefits

• For point-of-use to bulk flow specialty gas purification

• Low cost of ownership

• Wall mount frame – easy to install and operate

• Removes impurities to < 10 ppb (Dew Point = -150ºF)

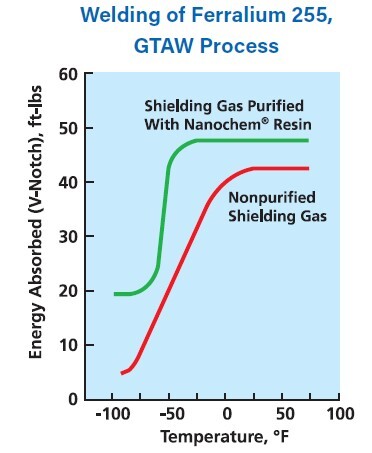

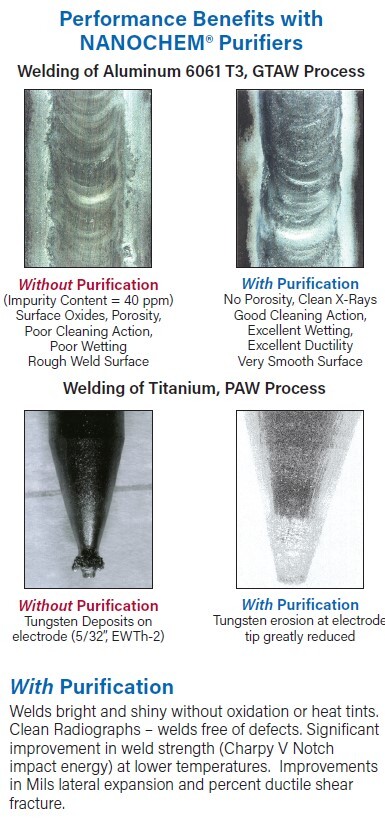

• Enhances weld quality, strength and appearance

• Reduces weld porosity and oxidation

• Increases weld electrode lifetime – No need to stop welding to grind/replace electrode

• Reduces weld rejects

• Built-in Bypass around purifier canister – Enables purging of gas lines without purifier deactivation during cylinder changeout

• Check valve at the purifier outlet – Prevents purifier deactivation from back diffusion of atmospheric air when gas flow is stopped

• Filters at canister inlet and outlet

• Operates at room temperature

• No power requirements

• NANOCHEM® Inorganic Media – Prevents contamination from system upsets, such as air intrusion or connection of wrong gas cylinder

• NANOCHEM® MigMix Purifier – Designed for customers with gas blend welding needs

• Field Replaceable Canister

• New Stainless Canisters can be refilled – Savings over cost of replacement canister. Reduction in generation of solid waste

| Part Number | Model Number | Max Flow# |

Media | Standard Impurities Removed |

Extra Impurities Removed |

| UEQ 10600551001 | WK-500-PA-OMX | 50 slpm | OMX™ | <100 ppt H2O, O2, CO2 LDL | |

| UEQ 10600551006 | WK-500-PA-INX-Plus | 50 slpm | INX-Plus™ | <100 ppt H2O, O2, CO2 LDL | <0.2 ppb Hydrocarbons except CH4 <100 ppt Halocarbons except CF4 |

| UEQ 10600552001 | WK-700-PA-OMX | 70 slpm | OMX™ | <100 ppt H2O, O2, CO2 LDL | |

| UEQ 10600552006 | WK-700-PA-INX-Plus | 70 slpm | INX-Plus™ | <100 ppt H2O, O2, CO2 LDL | <0.2 ppb Hydrocarbons except CH4 <100 ppt Halocarbons except CF4 |

| UEQ 10600553001 | WK-2500-PA-OMX | 250 slpm | OMX™ | <100 ppt H2O, O2, CO2 LDL | |

| UEQ 10600553006 | WK-2500-PA-INX-Plus | 250 slpm | INX-Plus™ | <100 ppt H2O, O2, CO2 LDL | <0.2 ppb Hydrocarbons except CH4 <100 ppt Halocarbons except CF4 |

#Note: Flow rates for argon

| Part Number | Model Number | Max Flow# |

Media | Standard Impurities Removed |

| UEQ 10600551002 | WK-500-PA-MM | 50 slpm | Mig Mix | <45 ppb H2O <0.2 ppb Hydrocarbons except CH4 <100 ppt Halocarbons except CF4 |

| UEQ 10600552002 | WK-700-PA-MM | 70 slpm | Mig Mix | <45 ppb H2O <0.2 ppb Hydrocarbons except CH4 <100 ppt Halocarbons except CF4 |

| UEQ 10600553002 | WK-2500-PA-MM | 250 slpm | Mig Mix | <45 ppb H2O <0.2 ppb Hydrocarbons except CH4 <100 ppt Halocarbons except CF4 |

#Note: Flow rates for argon

Materials of Construction

• Cannister: 316L stainless steel

• Valves: 316L stainless steel

• Fittings: 316L stainless steel

Specifications

• Maximum Operating Pressure: 200 psi

• Maximum Operating temperature: 104°F (40°C)

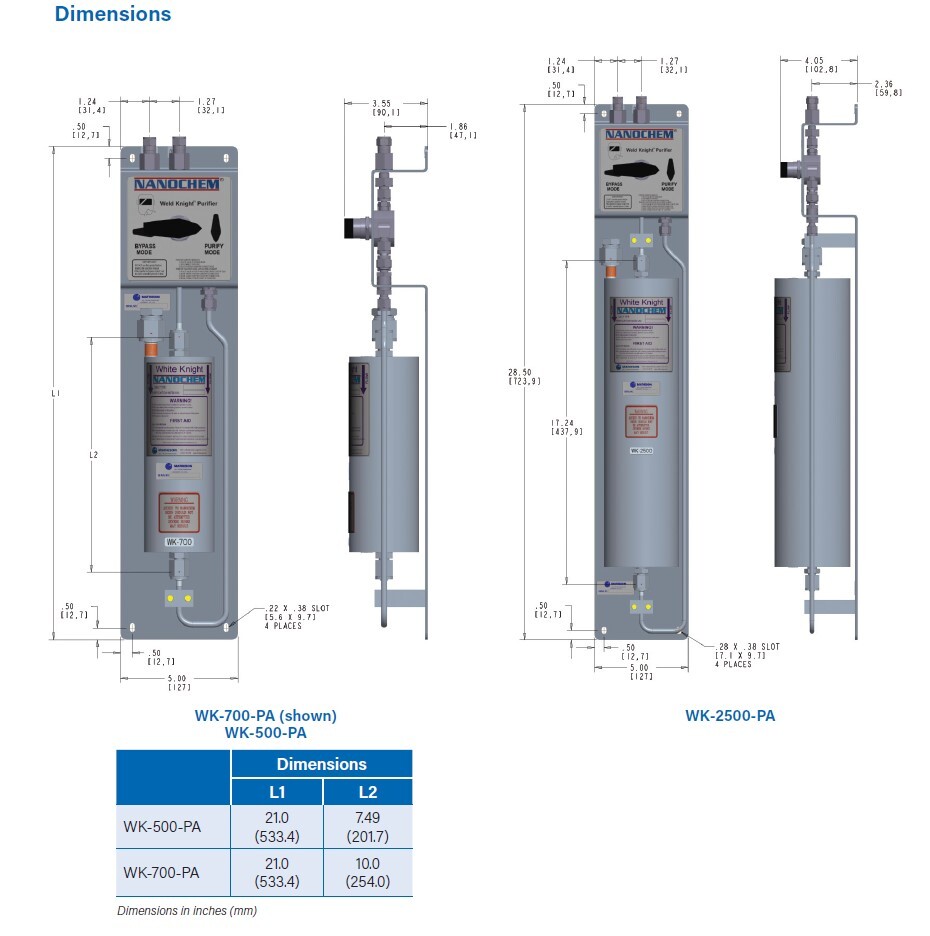

• Purifier Assembly Inlet/Outlet: 1/4" NPT - Female

• Cannister Inlet/Outlet: 1/4" Face Seal - Male

• Lifetime (approximate*) for (WK-500-PA): 105 cylinders

• Lifetime (approximate*) for (WK-700-PA): 147 cylinders

• Lifetime (approximate*) for (WK-2500-PA): 525 cylinders

*Based upon argon of 99.998% purity ("Pre-purified" grade) containing 3 ppm O2 and 10 ppm H2O

Loading... Please wait...

Loading... Please wait...