Products

Categories

- Home

- Specialty Gas Equipment

- 3D Metal Printing

- NANOCHEM® Purifier for 3D Metal Printing

Product Description

Gases such as argon, nitrogen, and various mixtures that are used for 3D Printing are generally available in sufficiently high purity grades. However, undesirable contamination by oxygen and/or moisture can occur in the gas delivery system, traceable to leaking fittings, contaminated gas delivery equipment, and contamination occurring during cylinder and equipment changeovers. Such system contamination events can lead to variable gas purity, which in turn leads to variable system performance and possible production defects.

In current high-performance 3D Printing (Additive Manufacturing) applications, gas borne contamination can lead to problems with:

• mechanical integrity of deposition

• inconsistencies of deposition

• purity of the printed structure itself

• printing tool orifice clogging and other issues with the printed product and the printing equipment.

Point of use gas purification using MATHESON 3DProTM Nanochem® Purifiers restores the purity of your gases by removing these rogue impurities, and, in turn, providing consistently high gas purity output at the printing tool.

MATHESON 3DProTM Nanochem® Purifiers are part of the MATHESON Nanochem® family of proprietary, advanced purification sorbents and systems. Nanochem® solutions are currently

implemented on a global scale in difficult applications in the semiconductor, pharmaceutical, aerospace, welding, and manufacturing industries. In a continuous-operation application such as 3D Printing,

MATHESON 3DProTM Nanochem® Purifiers feature high purification capacity (i.e., long lifetime), meaning that a purifier can be left on-line for long periods of time before replacement is required. Onboard endpoint detection with an optical sensor alerts the operator when the sorbent is approaching end-of-service.

Applications

MATHESON 3DProTM Nanochem® Purifiers are typically used to target the removal of water, oxygen, and carbon dioxide in argon, nitrogen, helium, and mixtures thereof. MATHESON 3DProTM Nanochem® Purifiers are also suitable for removal of other impurities and may be used in other matrices. If your application interest involves impurities or gases not mentioned above, please contact us. Alternate purifier choices may be applicable.

Features and Benefits

Benefits in 3D Printing Applications

• Removes impurities from source gas and from contaminants introduced by the gas delivery lines. This allows for less oxygen incorporated into the printed material.

• Less oxygen and water are expected to reduce the slag formation along with the reducing particle formations resulting in a less violent and more consistent printed parts.

• Less water adsorbed onto surface of powder and less oxygen in pores of the powder and in between powder particles will cause less mini-explosions at the POU resulting in smoother parts, and more controlled process.

• Stabilizes the printing process by eliminating variations due to gas line leaks, impurity fluctuations that occur from cylinder to cylinder or when a cylinder or bulk tank is replaced or refilled.

• A consistent moisture and oxygen level in the printing chamber will allow the powder to equilibrate to the chamber environment and result in a reproducible printing process.

Media (Sorbent) Features

• Inorganic purification material that removes oxygenated species such as water, oxygen, carbon dioxide, carbon monoxide, etc. down to < ppb levels.

• Longest lasting purifier material that reacts aggressively and irreversibly with impurities via a chemical reaction.

• Purifier can be used for inert gases such as argon and nitrogen in addition to other mixtures being used.

• Optical endpoint detector that measures the color change of the material using a proprietary glass to metal seal with no polymers. The purifier material changes color when it gets consumed by oxygenated species.

• Can be used with AC or DC power supply. DC power supply allows detector to be used with flammable gases.

• 40 μ particle filtration in addition to removal of oxygenated chemical impurities.

• Capable of high flow rates in excess of 50 slpm.

Hardware Features

• High Purity face seal connections provide lowest leak rates and allow easy purifier change outs compared to threaded or compression fittings. No polymer materials or threaded connections, eliminating virtual leaks.

• 316L SS body hardware with internal surface roughness of <15 μ Ra provides smooth, inert, and stable surfaces that is superior to other materials such as aluminum, brass, or carbon steel.

• Endpoint indicator makes it easy to determine when the purifier should be changed. Number drastically changes on the readout and light turns on.

• Maximum operating pressure of 150 psig.

• Inlet and outlet springless diaphragm valves included.

Combined Features

• Low total cost of ownership

• Requires little or no conditioning prior to use

• Easy installation – no heating or cooling required

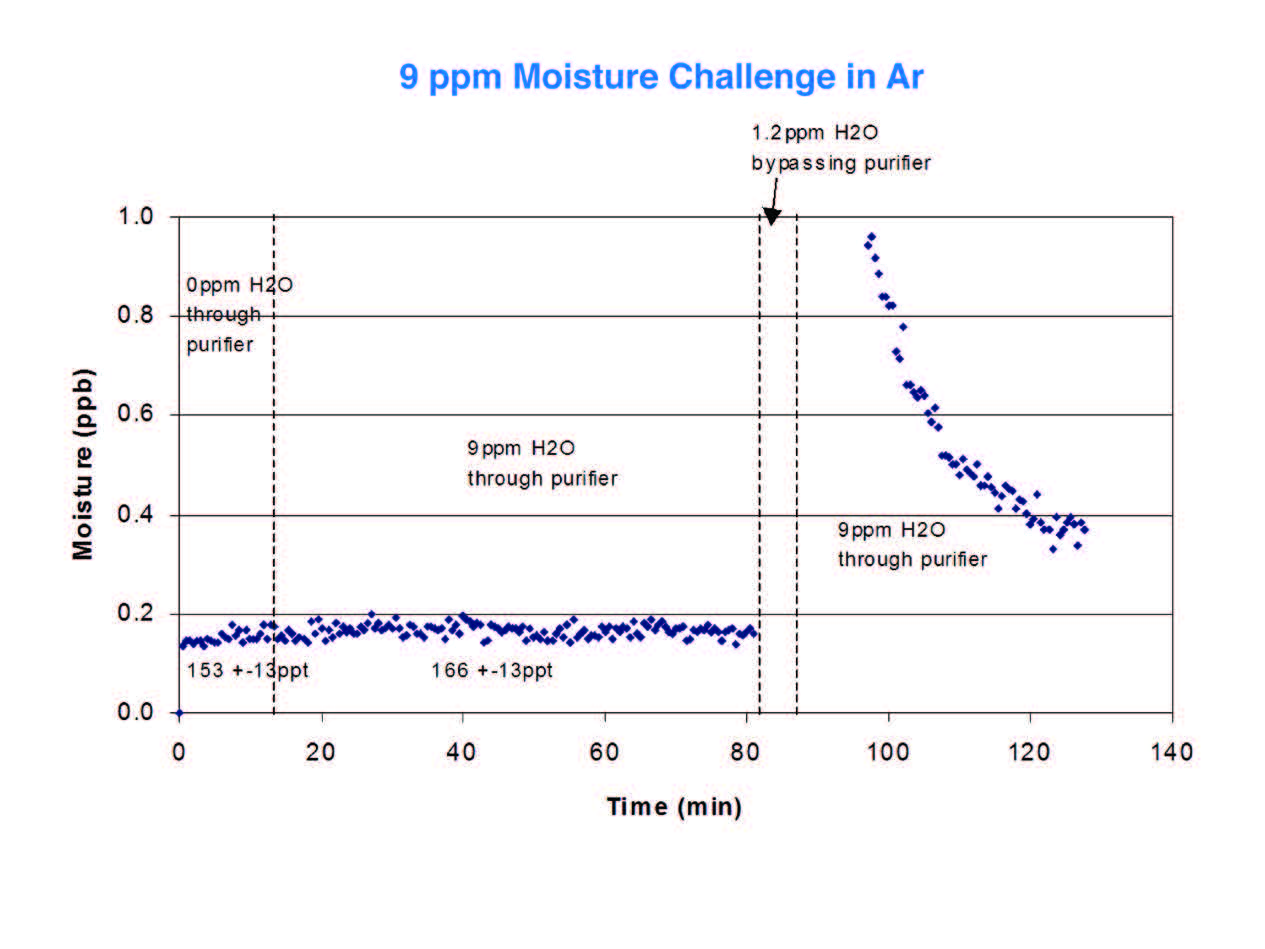

Typical Performance

Impurities are typically removed to the detection limits of state-of-the-art analytical techniques:

| Impurity | Efficiency (ppb) |

Challenge (ppm) |

| H2O in Ar | <0.3 (LDL*) | 35 |

| O2 in Ar | <0.14 (LDL) | 1 |

| CO2 in He | < 11 (LDL) | 500 |

*Lower Detectable Limit

MATHESON 3DProTM Nanochem® Purifiers deliver improvements in lifetime between replacements of approximately 5x for oxygen removal and 2x for water removal, compared to conventional purifiers. Actual results, of course, vary with application conditions and impurity levels.

MATHESON can provide an expected lifetime projection calculation based on your expected conditions. Please contact us for details.

Capacity & Efficiency in Argon

3DProTM Nanochem® Purifier with Nanochem® In2GOTM purification medium offers high capacities and efficiencies. The figure below shows that an inlet moisture content of 9 ppm in argon is reduced to < 0.2 ppb.

Notes:

• If your mix contains Carbon Monoxide or Oxygen then please contact us

• larger sizes are available

• This product includes hazardous materials. Transit time will vary by location. Product ships from Longmont, CO.

This product includes hazardous materials. Shipment of these products must be by common carrier. Expedited delivery is not available. Transit time will vary by location. Product ships from Longmont, CO.

Loading... Please wait...

Loading... Please wait...