Products

Categories

- Home

- Specialty Gas Equipment

- Regulators

- Modified Regulators "-S"

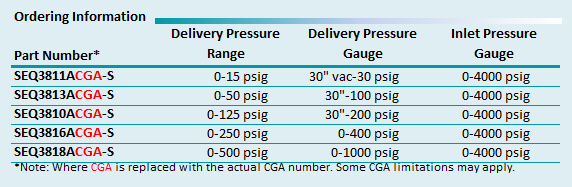

- 3810A-679-S Series Dual-Stage Regulator for Fluorine Mixtures - Stainless Steel

3810A-679-S Series Dual-Stage Regulator for Fluorine Mixtures - Stainless Steel

Request Quote

Product Description

A dual stage high-purity regulator designed for analytical applications using a less than 10% Fluorine mixture or less than 5% with a cross purge

Applications

• Supply of high-purity less than 10% Fluorine mixture or less than 5% with a cross purge to applications requiring constant delivery pressure.

Design Features

• High-purity 316 stainless steel barstock body

• High-purity 316 stainless steel diaphragm

• Metal to metal seals minimize diffusion of contaminants

• 2” inlet and delivery pressure gauges

• Bonnet ported and threaded to pipe gases away from work area

• Equipped with outlet diaphragm valve

• 1/4” compression tube outlet connection

• 10 micron metal filter protects seat from contamination

• Optional interstage relief valve available

• Panel mountable, front and back bonnet threaded

• Bonnet vent hole size: 1/8” NPTF

Materials of Construction

• Gauges: 316 stainless steel

• Body: 316 stainless steel

• Bonnets: Chrome plated brass barstock

• Diaphragms: 316 stainless steel

• Seats:

1st Stage – Teflon

2nd Stage – Teflon

• Seals: Metal to metal

• CGA inlet fitting: Monel

Specifications

• Maximum Inlet Pressure: 3000 psi (20,700 kPa)

• Typical Maximum Flow Rate (100 psi del press) : 7 SCFM (200 SLPM)

• Flow Capacity (Cv): 0.06

• Operating Temperature: -40°F to 140°F (-40°C to 60°C)

• Porting (Regulator Body): 1/4” NPT Female

• Porting Configuration: 2 High, 3 Low, l Interstage

Flow Curves

Flow Curves, 3120A/3810A Series

Loading... Please wait...

Loading... Please wait...