Products

Categories

- Home

- Specialty Gas Equipment

- Gas Delivery Systems

- Point of Use

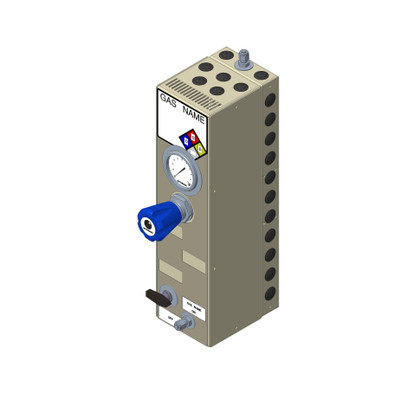

- GasTrak Pro™ - Gas Delivery System - SS

Product Description

Matheson’s GasTrak Pro™ Systems are a unique approach to controlling and delivering high-purity gases distributed in today’s modern laboratory. GasTrak Pro™ Systems offer dedicated control panels for specific functions and are designed to provide localized control of gas distributed within the laboratory. This equipment can be used as stand-alone, point-of-use gas panels or can be integrated into turnkey high-purity gas supply systems.

The basic design of the GasTrak Pro™ Systems product consists of individual panel sections snapped into place on a tube chase.

The system will accommodate any number of panel sections and future expansions can be engineered up-front decreasing the risk of the user’s investment becoming obsolete. This can substantially reduce the cost normally associated with expansion or modification.

System components are designed, cleaned and built to maintain gas purity. Panels are shipped leak-tested and completely assembled, keeping overall installation costs at a minimum.

Applications

• Provide the end-user with efficient control and delivery of multiple gases for individual instrument point-of-use or for controlling multiple gas sources within a single centralized system.

• Control the delivery of gases for several instruments, a specific zone (location) within a lab or the entire gas delivery requirements into a laboratory.

Design Features

• Allows user to maintain a consistent high-purity gas system.

• Provides localized control of gas pressure, purity and distribution at point-of-use with gas source located in a remote area.

• Modular snap-in panel sections provide unlimited flexibility.

• Easy to install - panels are shipped completely leak-tested and assembled.

• Low maintenance design - convenient access to panel sections.

• Panels enhance safety and reduce analytical variables when used in conjunction with an integrated gas delivery system.

• Panel graphics and valve labels customized for each application.

• Complete user-defined system with many options available

• Ideal for High (UHP 99.999%+) or Low Purity Gas Delivery

• Quarter-turn ball valves(s) for instrument isolation.

• Provides individual gas control/delivery stations for "point-of-use" delivery to analytical instruments.

• Gas specific labeling for each individual control/delivery station.

• Three Operating Pressure Ranges: 0-30 psi / 0-100 psi / 0-200 psi.

• 1/4" Compression Fitting Standard inlet connection

• 1/4" Compression Fitting outlet connection (front or bottom)

Materials of Construction

• Regulator: 316 Stainless Steel

• Valve: 316 Stainless Steel

• Gauge: 316 Stainless Steel

• Fittings: Stainless Steel

• Tubing: Stainless Steel

• Regulator Seat: Teflon

• Valve Seat: Kel-F

• Section Housing: Powder-coated epoxy finish over zinc chromate treated steel

Specifications

• Maximum Inlet Pressure: 400 psi (2,760 kPa)

• Flow Capacity (Cv): 0.08

• Operating Temperature: -15°F to 140°F (-26°C to 60°C

• Inlet: 1/4" Compression

• Oultet(s): 1/4" Compression

Loading... Please wait...

Loading... Please wait...