Products

Categories

- Home

- Specialty Gas Equipment

- Gas Detection

- 8058 General Purpose Gas Detector

Product Description

The Model 8058 General Purpose Gas Detector effectively monitors the workplace air for potentially dangerous gas leaks from tubing, equipment, containers, reaction vessels, cylinder valves, and pressurized systems.

Weighing only 7-1/2 ounces, this truly portable and personal detector can be conveniently carried.

The unit continuously samples the air for hazardous gases and vapors. It sounds an audible alarm and flashes an LED when a potentially dangerous concentration of gas is detected.

The Model 8058 sensor design is sensitive to a wide variety of gases and vapors.

Applications

The Model 8058 functions as a personal gas leak detector for production, QC, maintenance, and engineering personnel in a wide variety of process and laboratory locations and environments. Personnel no longer need be within the “sphere of influence’’ of a large multipoint gas detection system. They can now take their personal gas leak detectors with them, on site where needed. Since personal protection is only as good as the sampling procedure used, different areas should be checked for gas leaks that could lead to potential worker exposure.

Leak Detection

The Model 8058 also functions as a point source leak detector for process and instrumentation gases. With the accessory probe attached, it can give an early warning indication of small leaks in cylinder or piping connections, or other gas handling hardware before they become large, potentially dangerous leaks. A comprehensive floor-to-ceiling scan procedure should be used for maximum effectiveness in leak detection.

Gas Cabinet Cylinder Changeover

The Model 8058 has applications in leak detection of valves, fittings, purge assemblies and other hardware during cylinder changes in gas cabinets.

Process Vessels and Enclosures

The Model 8058 can be used to detect leaks from process vessels, storage tanks, reaction vessels, and associated piping. It is good practice to periodically check process and associated equipment and materials for leakage before serious, potentially dangerous leaks have developed.

Remote Enclosed Areas/Ductwork Leak Detection

It is also good practice to check the workplace air in remote and/or enclosed unmonitored areas before workers enter them. The same holds for large ductwork and ventilation systems that, during shutdown for maintenance and engineering work, can contain trapped pockets of hazardous gases. The Model 8058 can be used to sample these and other areas for leaks of potentially hazardous gases to help ensure a safe environment both before and during work tasks. Proper oxygen concentration should also be determined in remote or enclosed areas before workers enter.

Cylinder Storage Areas

It is also good practice to screen incoming gas cylinders (both on receipt and return shipments) for possible leakage around cylinder valves. The Model 8058 with probe simplifies this process because of its small size and weight. The probe can be inserted into the slots in the cylinder cap for fast leak detection. Because gas leaks can stratify, a comprehensive floor-to-ceiling scan procedure should be used to detect accumulations of potentially hazardous gas leaks in cylinder storage areas.

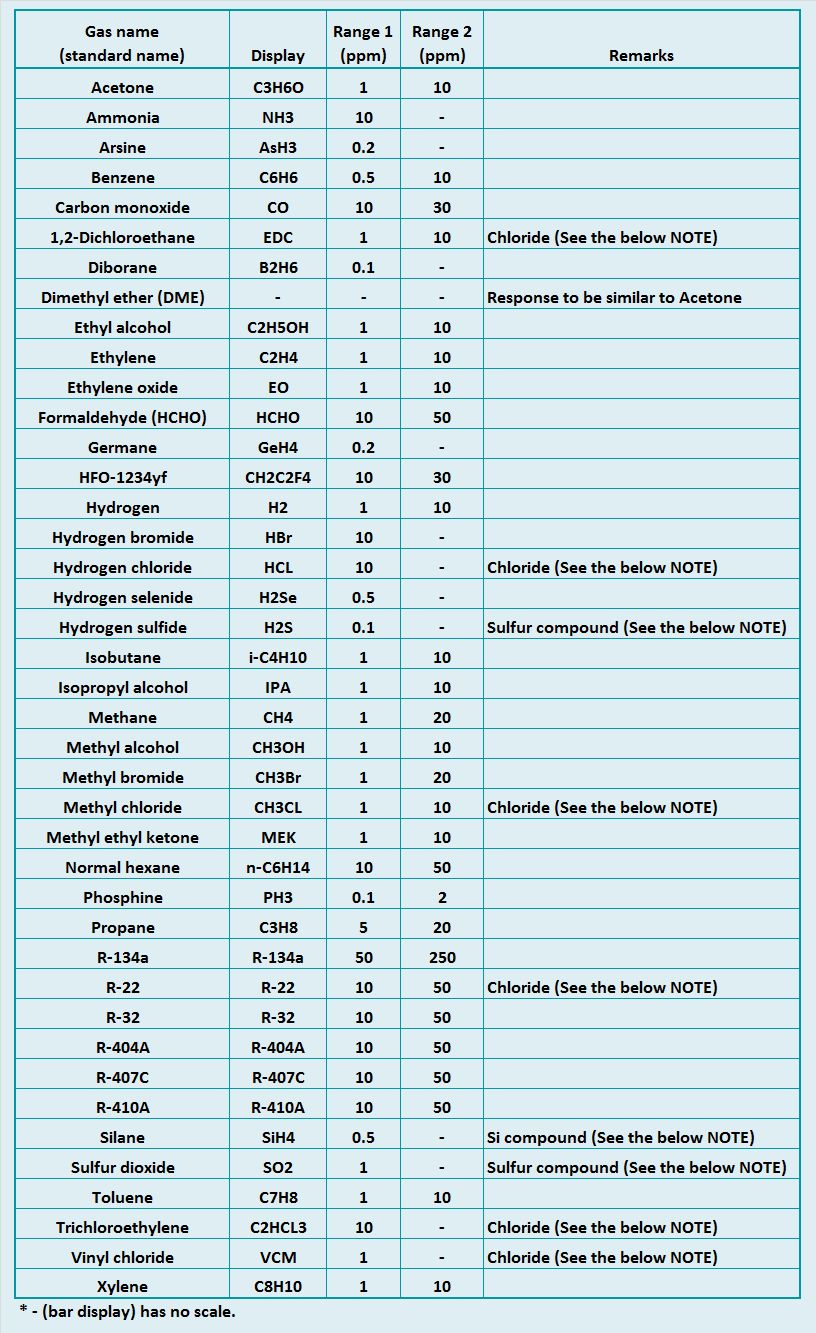

Gases Detected

NOTE

· High-concentration or continuous contact with a chloride or sulfur compound will shorten the sensor life or cause larger errors.

· If a Si compound is detected, the sensitivity will decrease.

· Even for a gas shown only with the bar meter display but no scales, the meter reads Scale 2. Use it as an indication of concentration increase.

· If a high-concentration solvent gas is drawn, the rubber seal used in the detector will deteriorate.

Specifications

| Detection principle | Hot-wire semiconductor |

| Gas Alarm Type | Gas concentration reaches or exceeds the alarm setpoint value. |

| Fault Alarm Type | Sensor connection/disconnection, low battery, low flow rate, circuit abnormality, calibration range abnormality, clock abnormality and pump abnormality |

| Gas Alarm Operation | Lamp blinking and intermittent buzzer sounding |

| Fault Alarm Operation | Lamp blinking, intermittent buzzer sounding and fault detail display |

| Detection method | Pump suction type |

| Sensor Type | Metal Oxide Semiconductor (MOS) |

| Sensor Lifetime | 2-5 years |

| Response time | Within ten seconds of 0.1 ppm alarm by contact with PH3: 0.3 ppm |

| LCD display | Display contents: Gas name, gas concentration (scale + bar display), time, battery level, drawing, operation and mode |

| Power supply | AA alkaline battery: 2 (included) |

| Continuous operating time | 12 hours or more (normal temperature, without alarms or lighting) |

| Operating environment | Temperature range: -20 - +55ºC |

| Humidity range: 95%RH or less (Non-condensing) | |

| External dimensions | External dimensions: 43 (W) x 200 (H) x 39 (D) mm (projection portions excluded) |

| Weight | Approx. 7-1/2 oz |

| Ingess Protection | Equivalent to IP-55 |

| Functions | Target gas selection |

| LCD backlight (automatically lights up in response to an alarm) | |

| Peak hold | |

| Data logger | |

| Clock display | |

| Standard Accessories | Tapered nozzle (1 pc) |

| Rubber protection cover (1 pc) | |

| Hand strap (1 pc) | |

| Spare filters (5 pcs) |

Instructions, 8058 Gas Detector

Loading... Please wait...

Loading... Please wait...